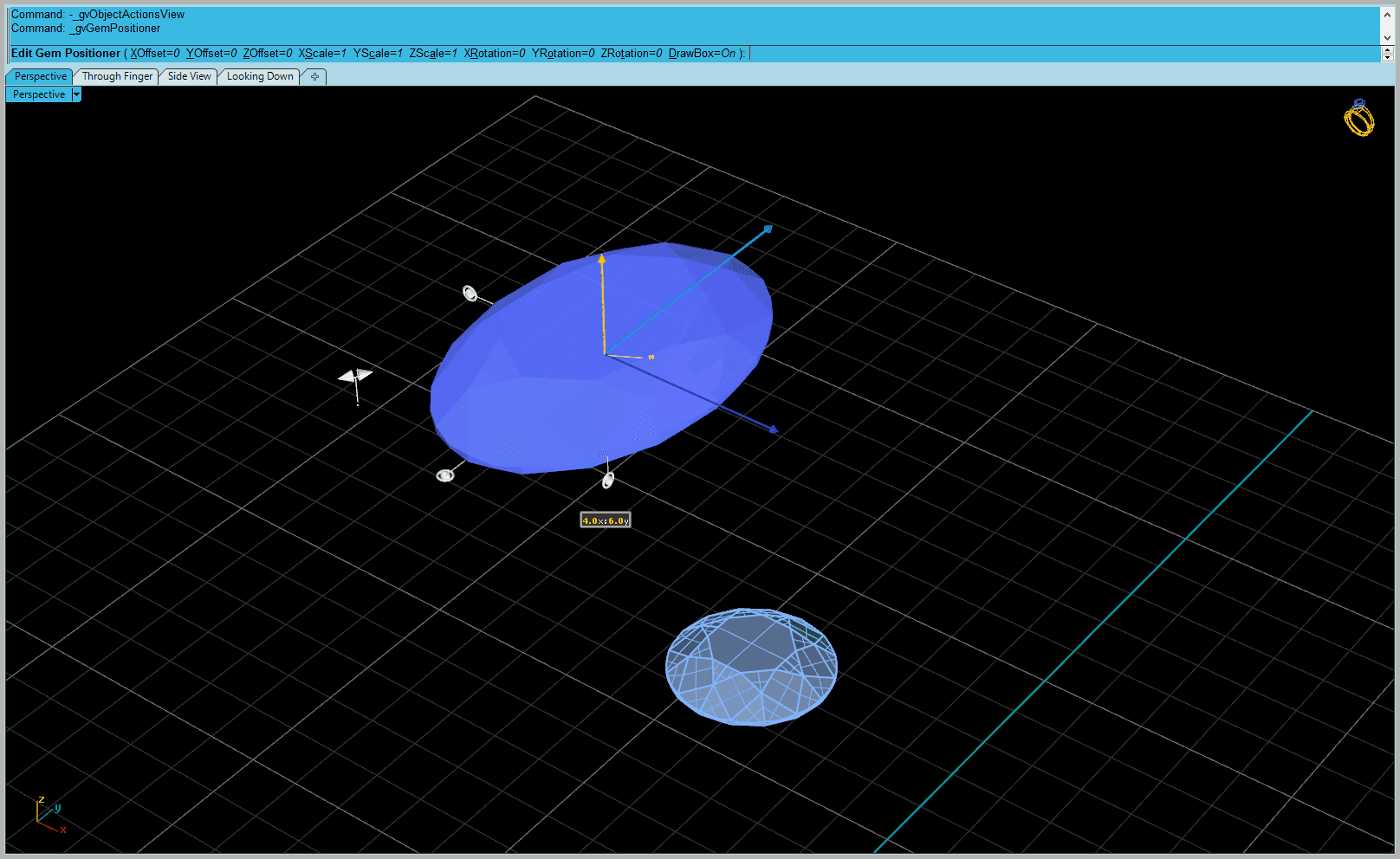

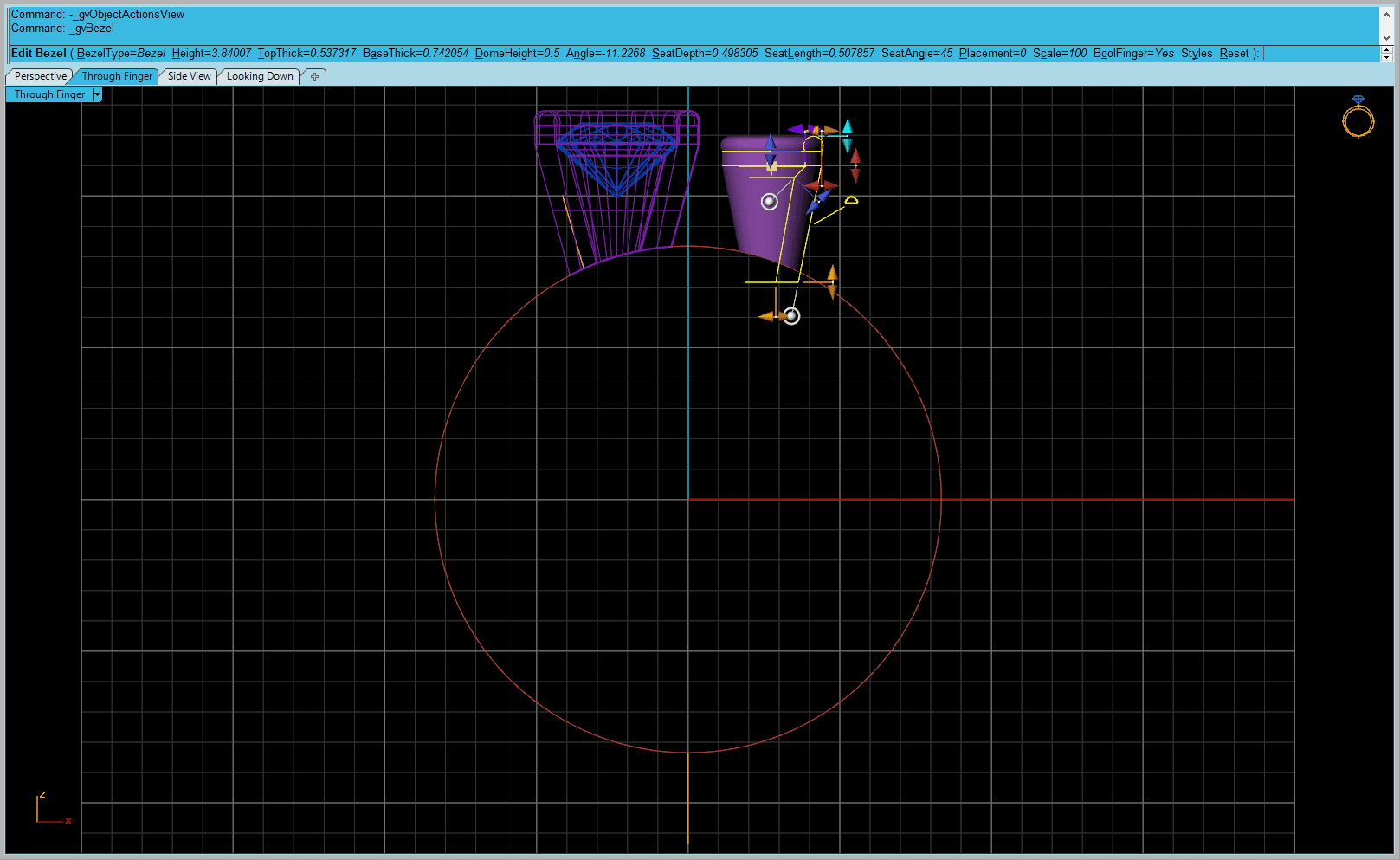

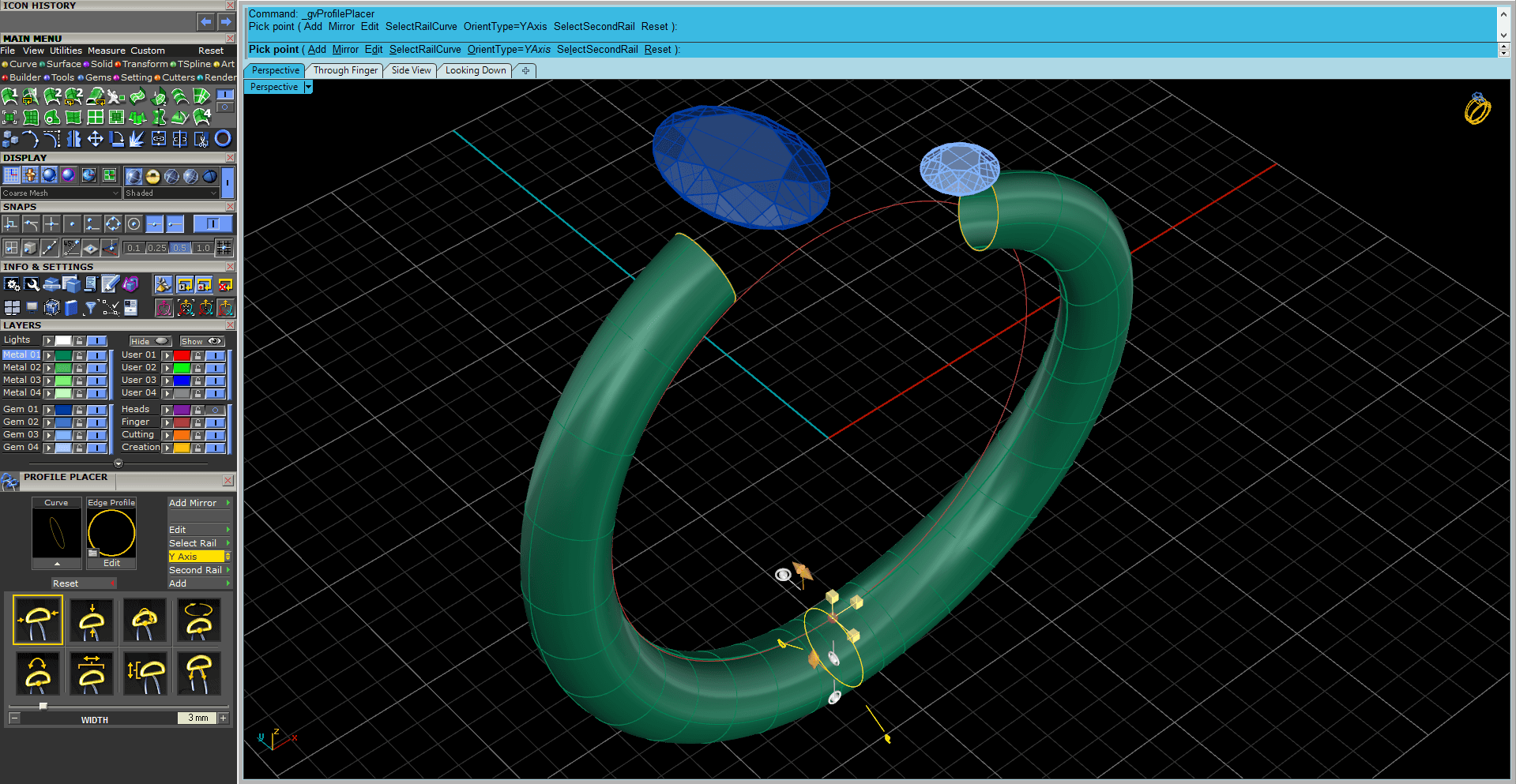

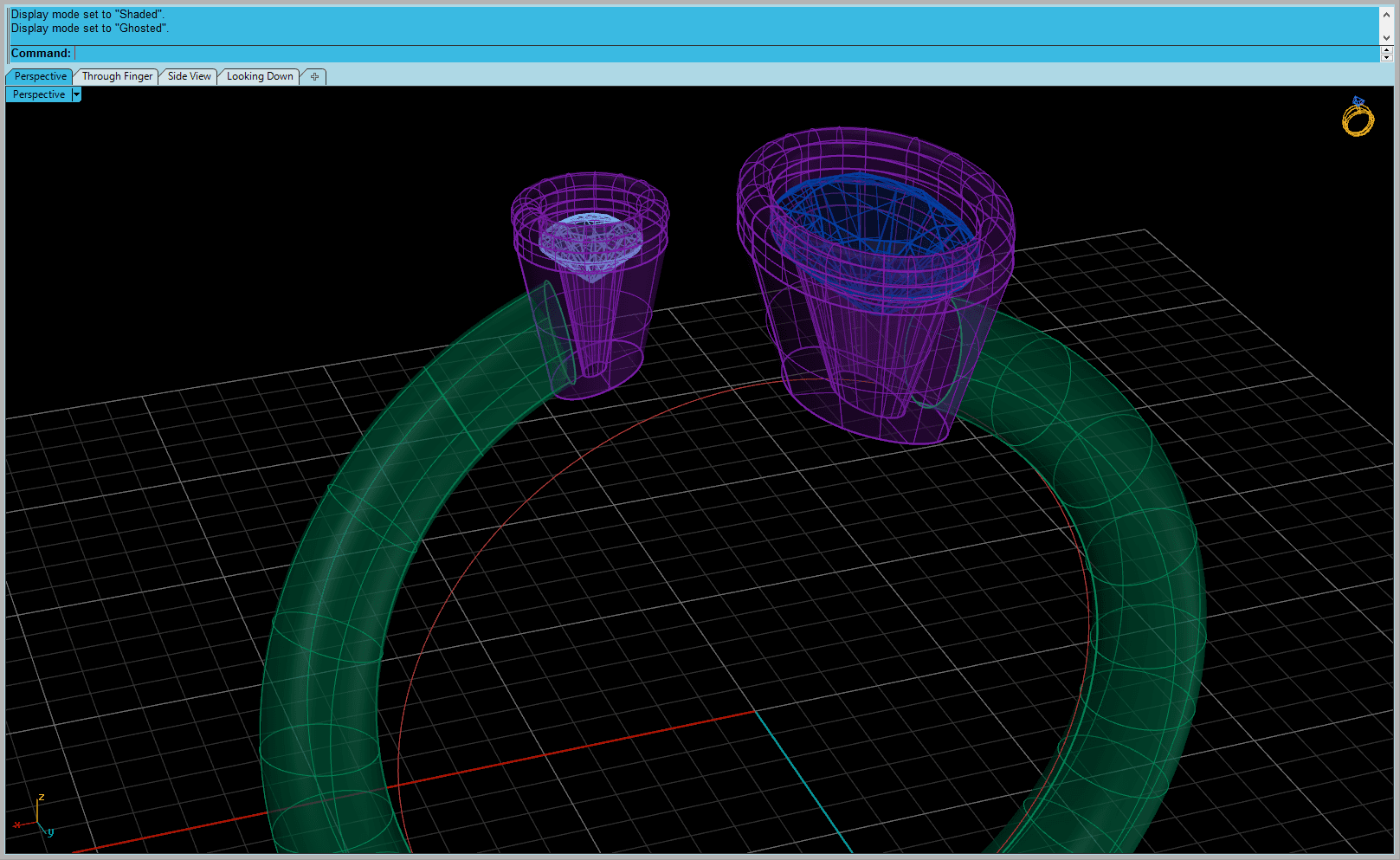

After a consultation with our customer to discuss design & choice of stones, it was decided to create a totally bespoke, handmade ring in yellow gold, to feature a central Amethyst & Diamonds surrounding.

The customer chose an oval cabochon cut oval Amethyst, 12mm x 10mm in size & approximately 4.1 carats in weight. The Diamond surround has 20 high grade, round brilliant cut diamonds of 0.40 carats in total. These diamonds are G in colour & SI in clarity.

The ring setting & shank were made in 9ct yellow gold, including a small enclosed box, which sits underneath the amethyst. This small box was specifically designed to house some ashes.

A small amount of ashes were carefully placed within & sealed over with a secure gold plate, on which the amethyst now rests. The stone was then set in place with a gold bezel edge.

The most romantic cut of all, the heart cut is perfect for a sentimental diamond engagement ring.

The heart shaped cut dates back to 1562 and has long been a symbol of love and friendship. It is the ultimate diamond shape for sentimental diamond gifts or engagement rings.

Symmetry is very important for this diamond shape, as both halves of the stone need to match. Only extremely skilled diamond cutters are able to cut this intricate shape.

The heart shaped cut is a modified version of the brilliant cut diamond, usually comprising of 56 to 58 facets, with the pavilion facets varying between 6, 7 and 8.

This diamond looks stunning set in earrings, pendants, engagement rings and alongside different gemstones. To make sure the heart shape does not remain unnoticed, we recommend choosing a diamond above 0.50ct or half carat in weight.

Our Workshop “Elves” are so very busy at the moment, creating stunning sparklers for Christmas.

Today, I’m proud to feature this incredible diamond band ring. Crafted in 18ct white gold, it has two rows of multi-coloured diamonds. All are round brilliant cut white, yellow, blue & green diamonds (irradiated colours) of 0.52 carats in total weight. The white diamonds are G in colour & VS in clarity.

In store right now, we only have this one. Priced at £1,700.00 in size M, it’s a design that is sure to command longing looks & wonderful comments from all who see it.

Recently, a wonderful customer made an enquiry regarding the possibilities for re-using her own gemstones into a new piece of jewellery.

There were 9 stones in total to be taken from 4 of her own rings, all of which had great sentimental value. William was shown a 5 x 4mm oval sapphire of 0.40ct, a 4mm round sapphire of 0.25ct, a 4mm round ruby of 0.25ct & 6 round brilliant cut diamonds of various sizes, totalling 0.51ct.

After having a chat & discussing her requirements, the customer decided on a brand new ring of 6mm wide in 9ct yellow gold in a band style. The ruby & 2 sapphires were all then bezel set into the band & the 6 diamonds invisibly set into the band, to give a variation within the ring.

She decided also to have the stones set in a very unusual uneven & quite random “scatter” design, with the central oval sapphire (the largest stone) to be set at an angle rather than vertical or horizontal.

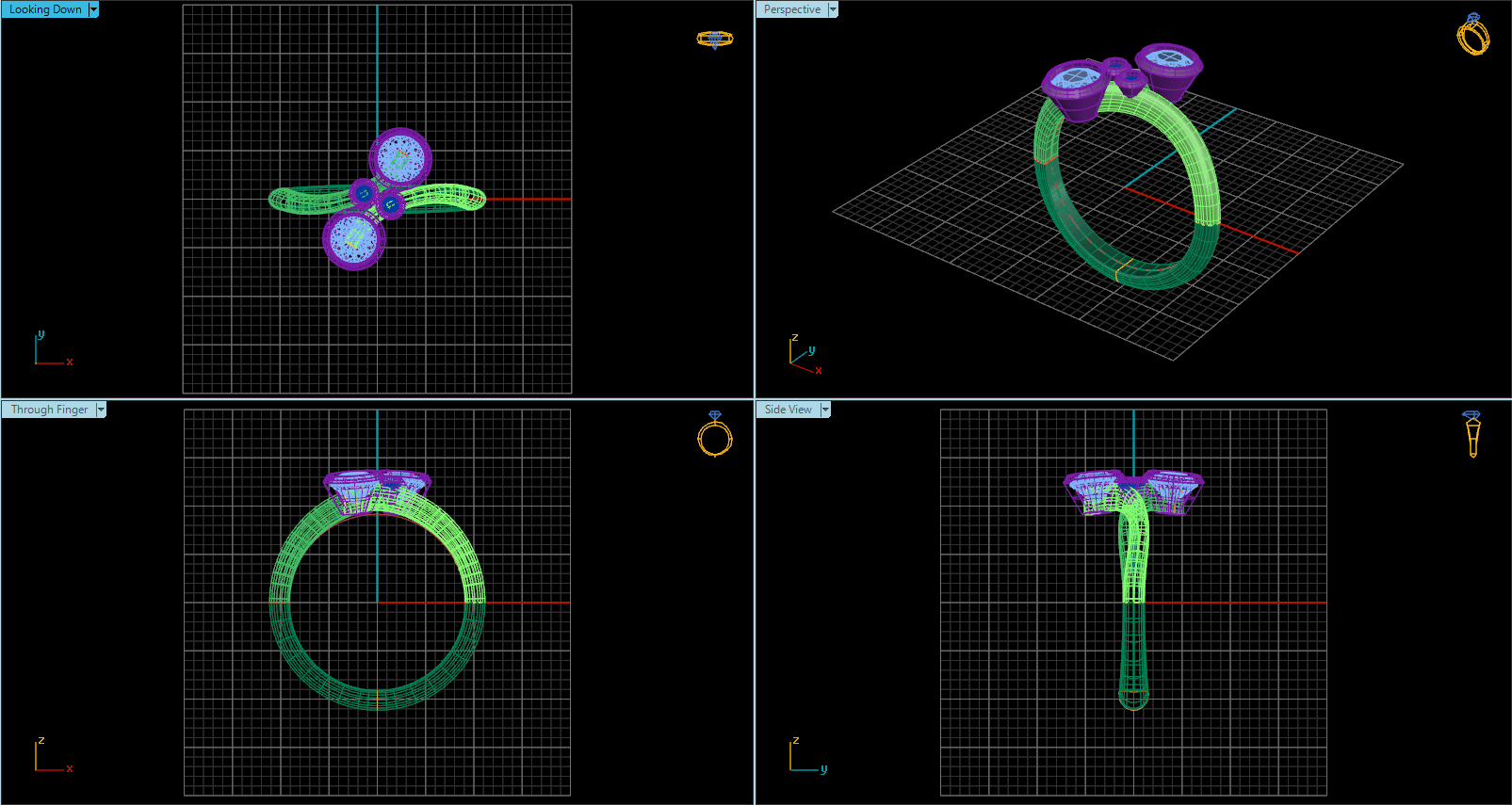

A very lucky member of staff here at William & Julia Shaw Jewellers is the proud owner of this bespoke Aquamarine ring.

She spotted the loose, more unusual heart-cut stone with a rarer & strong aqua colour in our workshop & had a “significant” birthday coming up, so made enquiries about having the stone set into a ring.

The stone measures 13mm & is 5.26 carats, which meant

that the setting had to be created using our CAD technology. After choosing

white gold for the ring & seeing the CAD on screen, she made a couple of

adjustments to the width of the band & the 3 claw setting. Once happy with

the design, the ring was cast in white gold & then sent to the Assay Office

for hallmarking. Our loose Aquamarine was then hand-set into the ring by one of our experienced working jewellers.

This is the result – another fabulous & truly unique piece of heirloom jewellery that will be loved & cherished by it’s owner for ever.

We were recently approached by a lovely lady, with a request for a ladies yellow gold Memorial bracelet.

After initial discussions in our Dodworth store, a design was decided upon, using 9ct yellow gold. Due to the importance of the piece, we created the bracelet using heavy curb bracelet links, with a centre section measuring 30mm in length, 10mm in width & a depth of 5mm. The centre section you see here was hand-made as an open box design from 9ct yellow gold sheet, created to contain a small amount of ashes.

After hand-crafting this centre section & attaching it to the bracelet links, the ashes were very carefully placed inside. The lid was then laser-welded on to seal the box.

Once the secured lid was polished, the flower design was hand-engraved at each corner.

The unique & beautiful “Slippery Elm” leaf design of these drop earrings was specially requested by our customer, as each letter of the word E.L.M.S represents an initial of a family member’s name. (On further investigation, we discovered that the Slippery Elm is a species of elm tree, native to Eastern North America).

For each earring, the leaves; approximately 25mm in length, were pierced out by hand from silver sheet & also textured by hand.

Each leaf was then set with a ruby & a sapphire, which are the birthstones for July & September – the birth months of the customer’s grandchildren.

Finally, the gold plating was applied to some of the veins of the leaves & the hook fittings were securely attached to the loops.

A customer called recently with an enquiry regarding a sentimental piece of jewellery. She made an appointment & brought her old wedding band ring into the store to discuss her thoughts about how best to make use of it with William.

After an initial consultation & chat, the lady in question decided on a bangle. We measured the customer’s wrist & took the correct size. William then made a bespoke bangle in 9ct yellow gold & it was checked for size before continuing.

As you’ll see from the images, there are 4 sections which we applied to the bangle. Each section was created using diagonal, full width sections cut from her old wedding band ring. Each of these sections was shaped, with an emphasis made on the original nibbed edging & then soldered onto the bangle.

After being hallmarked at Sheffield Assay Office, the bangle was then pave hand-set with diamonds & emeralds in our workshop - each section having one round cut, fine quality emerald & two round brilliant cut diamonds, which we supplied. In total the four emeralds are 0.12cts & the eight diamonds are 0.12cts.

We know how much you love to see our bespoke pieces & of course, we love to show them to you!

Feast your eyes on this totally stunning engagement ring.

Created using our CAD design service, this bespoke ring has been crafted in 18ct rose gold. Featuring a centre pear cut diamond which is set into platinum, this certified stone has a halo of diamonds surrounding it & also features intricately shaped & vintage-inspired diamond-set shoulders.

The total carat weight of this exquisite ring is 0.98ct

I’m sure that you’ll agree that it’s a real work of art. We are delighted to say our customer is thrilled with her engagement ring – who wouldn’t be? We are proud to have been chosen to create it for her.

We know that jewellery is purchased for a special reason. Whether it’s the ultimate engagement or wedding ring, an anniversary, or any other celebration piece, our Dodworth store can offer you a tailored & often bespoke service. In our store, you can comfortably make your purchase at your own pace. View alternatives available in our extensive stock to ensure you make the right decision for you. We feel that such a special piece deserves your input & for you to be a part of it’s creation.

Our working jewellers here are always on-hand to answer any questions or concerns you may have. Teamed with our friendly & helpful team & private consultation room, to a truly personal service from concept to completion, we pride ourselves on bringing you an unforgettable experience.

One such recent experience was from a wonderful couple, who wanted a bespoke Ruby Wedding gift.

After making an appointment to see William, they came with an idea downloaded from a vintage ring they saw online, copied on a piece of paper. Emily, who creates our CAD designs joined the discussion & tweaked the original image to incorporate larger stones & a slight variation on the setting. She then created a computer aided design to their specific requirements & contacted our couple to view this before going any further.